product description

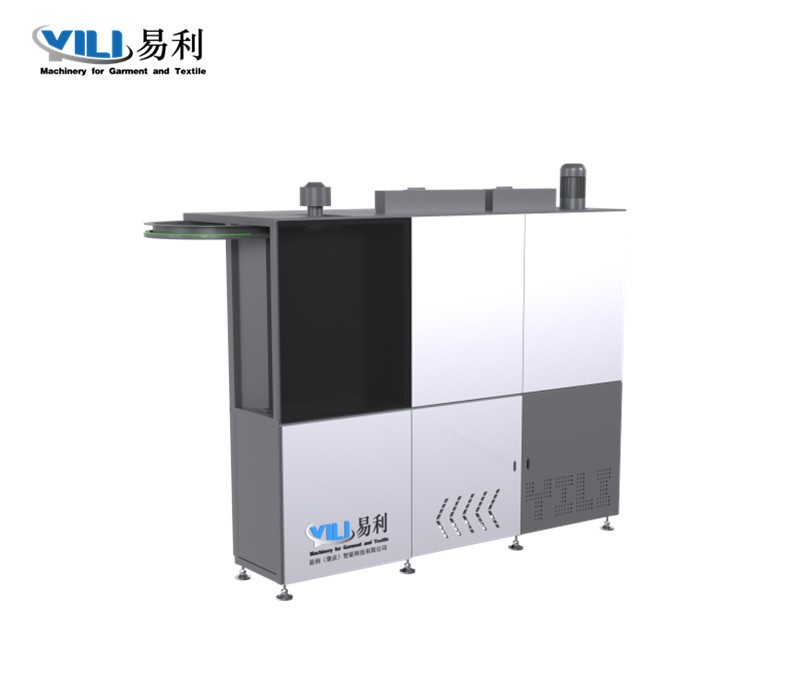

Steam ironing and finishing: with automatic sensing and positioning function, accurately grasp the size of clothing, automatic steam ironing of clothing with mechanical hand to ensure the ironing effect, and equipped with brush to smooth the surface of clothing, eliminate wrinkles of clothing.

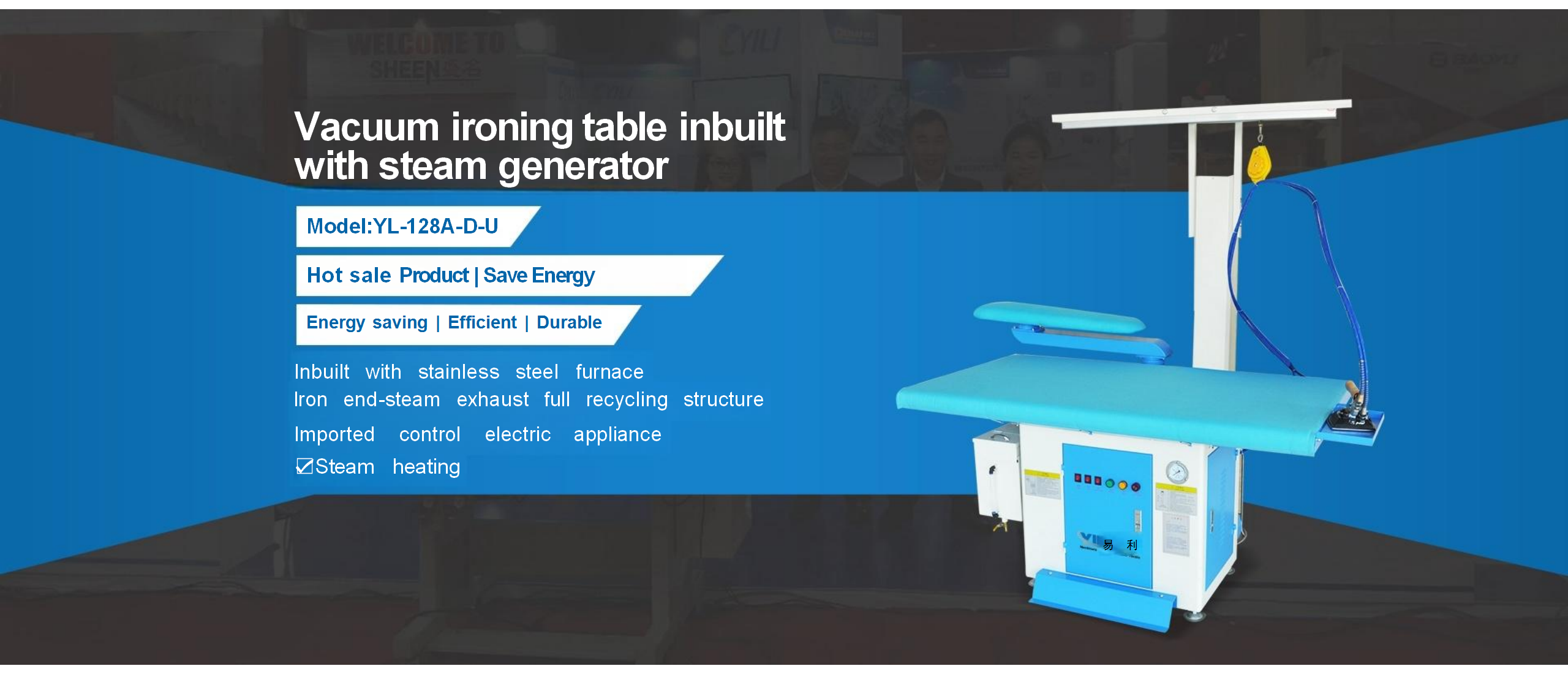

Built-in electric heating steam boiler, reduce pipeline loss and temperature loss; And equipped with steam recovery system, minimize the use of energy consumption.

Drying and cooling: use hot air circulation structure to dry the clothes, the process is gentle, will not damage the clothes. The cold air cools the clothes. Avoid the phenomenon of mildew after clothing packaging in rainy weather.

Optional spray device, add fabric softener, color protectant, etc

Functional feature:

High quality: unique ironing principle, ensure good ironing effect, and no damage to clothing.

High efficiency: automatic rail transport, and with independent working area (steam ironing finishing area, hot air drying setting area, cooling area).

Energy saving: unique ironing principle, use less steam; The working environment is relatively sealed to achieve the best heat preservation effect and reduce steam loss.

Performance feature:

1. Use electrical automation control components and PLC program module to control the running process of each area.

2. Unique positioning system and ironing principle, good ironing effect.

3. Servo drive, accurate positioning, fast operation efficiency.

4. Transport hook chain has tension adjustment system.

5. Visual operation process, equipped with modern touch screen for flexible control

Operation process:

The clothes are automatically transported into the tunnel ironing machine through the rail, and after steam ironing, brush finishing, hot air drying and cooling, the clothes are automatically transported out of the tunnel ironing machine, so as to achieve high quality and low energy consumption of batch clothing ironing and finishing, saving labor costs and realizing automatic ironing.